MAGTITE® 2000™ screws are TRILOBULAR® thread forming screws designed expressly for fastening magnesium die castings. Magnesium presents difficulties in the area of fastening, especially when using thread forming fasteners. Since many aluminum alloy die cast components utilize reminc’s/CONTI's thread rolling fasteners, the challenge to reminc/CONTI was to maintain the cost savings achieved when using the TAPTITE® family of fasteners in aluminum and zinc alloy castings, in their new magnesium counterparts. The transfer to magnesium die castings led to the development of MAGTITE® 2000™ special thread forming screws.

MAGTITE® 2000™ screws are TRILOBULAR® thread forming screws designed expressly for fastening magnesium die castings. Magnesium presents difficulties in the area of fastening, especially when using thread forming fasteners. Since many aluminum alloy die cast components utilize reminc’s/CONTI's thread rolling fasteners, the challenge to reminc/CONTI was to maintain the cost savings achieved when using the TAPTITE® family of fasteners in aluminum and zinc alloy castings, in their new magnesium counterparts. The transfer to magnesium die castings led to the development of MAGTITE® 2000™ special thread forming screws.

It’s The Shape

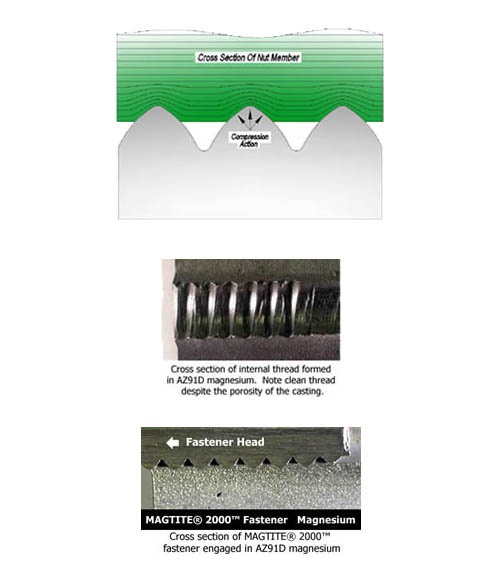

MAGTITE® 2000™ screws have a TRILOBULAR® body configured to suit the low elasticity of magnesium, and a broad Radius Profile™ thread, which forms internal threads primarily by compressing the magnesium.

MAGTITE® 2000™ screws have a TRILOBULAR® body configured to suit the low elasticity of magnesium, and a broad Radius Profile™ thread, which forms internal threads primarily by compressing the magnesium.

Results and Benefits

The compression action of the Radius Profile™ thread results in little to no debris generated during the thread forming process in this friable material. In addition, MAGTITE® 2000™ screws fail by fracture as opposed to stripping of the internal threads, when inserted at a depth of 2 to 2½ times the screw’s nominal diameter (dependent on material grade and casting process). The benefit achieved when using MAGTITE® 2000™ screws is greater material and weight savings since a casting design will not require extra mass at the fastening sites.